Raised Edge Conveyor Belts

Characteristics

Belt Carcass: cotton(CC),Nylon(NN),and Polyester and nylon(EP).

(1) Materials can be conveyed at a large alope up to 90°.

(2) The belt has large loading capacity and the materials can not be scaltered.

(3) The slope of conveying can be changed fron horizontal to sloping, or from sloping to horizontal.(4) The conveyor is simple in structure,flexible in arrangement and occupy only a small area.

Usage

Raised edge conveyor belt , which is suficient to prevent scatter of conveyed materials, is suitable for space limitation or conveying materials at large slope from 0°to 90°.

- Monsterbelts increases transport capacity up to 3 times compared to other types of traditional belts on the same width range.

- It saves space by allowing the vertical elevation of materials, up to a gradient of 90º.

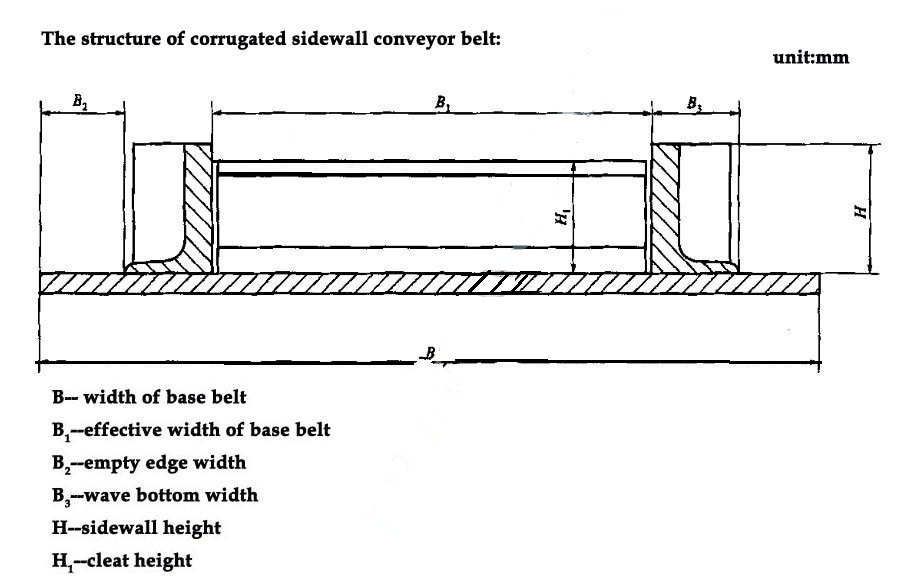

- Sidewalls are manufactured in a wide range of heights, from 40 mm up to 600 mm.

- All sidewalls can be produced with a fabric reinforcement insert, particularly recommended for heights over 140 mm and necessary for heights of 160 mm and above.

- The design of our sidewalls offers great vertical resistance, which adds greater stability to the belt and maintains a high degree of flexibility while allowing it to adapt to lower diameter pulleys.

- Cleats are always manufactured by press moulding. The quality or type of rubber used depends on the specifications of the product to be conveyed, fulfilling at all times the most demanding levels of wear resistance and abrasion strength.

- This system allows for an economical structural installation, since it provides a single means of conveying materials, depending on the elevation height, where at least three conventional conveyors would have been necessary otherwise.

- Its maintenance cost is lower than that of a regular conveyor belts system.

- The levels of adhesion gained through hot vulcanizing are 15 times better than those offered by the traditional means of ‘’cold splicing’’ used by some companies nowadays. Our hot vulcanized sidewalls and cleats belts have no risk of dismembering of the different elements due to their hot vulcanizing technology.

- Our cleats can be manufactured with or without fabric reinforcement. However, for cleats above 320 mm in height, we highly recommend the use of fabric reinforcement.

The recommended height of the cleats should be 10 to 20 mm lower than the height of the sidewalls.

Cleats type T, C, TC and TSC different mainly in their load capacity, and the choice will always depend on transportation needs.

Type TCFX consists of three elements: two bases joint to the belt and a cross cleat elevation screwed to the bases, which is always manufactured with fabric reinforcement.

RUBBER QUALITY: