Flame Resistant for Underground Mining

Our steel cord conveyor belts are distinguished by their extremely high transmission of forces, long lengths and very high load-carrying capacities.

Our rubber engineers have develop a wide range of flame-resistant and anti-statics compound, in addition to satisfying underground requirement. The fire Resistance Conveyor Belt In Coal most.

ST Fire Resistant Conveyor Belt

Standard of Flame Resistant

Belt Property:

- Tensile Strength: ≧ 15MPa

- Elongation: ≧ 350%

- Ageing Test: (70°C x 168h)

- Tensile Strength Rate: ±25%

- Elongation Strength Rate: ±25%

- Din: ≦ 200mm3

Cord Rubber Compound Penetration:

- The average steel belts of adhesion strength does not less than 85% after aging.

- In cover rubber and adhesive layer, the average of adhesion strength does not less than 10 KN/M.

- Containing fabric in flame resistant steel cord belts, the average of adhesion does not less than 8 KN/M in rubber cover and adhesion.

Rubber Permeability:

- 100kPa pressure is applied to both edge in the test pieces, with 60 seconds, the difference does no more than 5kPa.

Adhesion of Steel Cord Belts:

- 10,000 times cycle test, steel cord belts without any pull-out phenomenon.

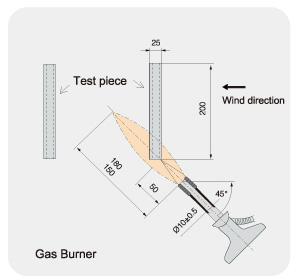

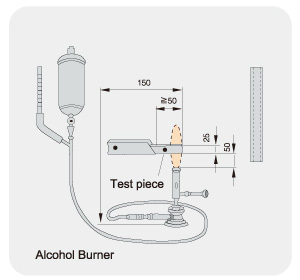

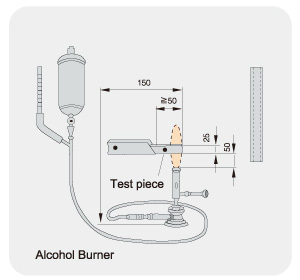

Burning Test

| Item | Standard | |||

|---|---|---|---|---|

| Electrical Resistance | Electrical Resistance | ≦ 3 x 108 | ||

| Drum Friction Test | Drum surface temperature. | ≦ 325 | ||

| Test pieces shall not show not sign of flame. | ||||

| Finger Burn Test S = sec |

With Covers | The self-extinguish average time of six samples (S) | ≦ 3 | |

| The self-extinguish time of one sample (S) | ≦ 10 | |||

| Wihout Cover | The self-extinguish average time of six samples (S) | ≦ 5 | ||

| The self-extinguish time of one sample (S) | ≦ 15 | |||

| Gallery Test | Test result confort to (a) or (b) | (a) | Each Samples Undamaged Length (mm) | ≧ 600 |

| (b) | Each Samples Undamaged Length (mm) | ≧ 50 | ||

| Max. Average Temperature (°C) | ≦ 140 | |||

| Damaged Length (mm) | ≦ 1250 | |||

Thickness of Flame Resistant Rubber

| Designation | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST1800 | ST000 | ST2500 | ST2800 |

|---|---|---|---|---|---|---|---|---|---|

| Top Cover ≧ | 5.0 | 5.0 | 6.0 | 6.0 | 6.0 | 8.0 | 8.0 | 8.0 | 8.0 |

| Bottom Cover ≧ | 5.0 | 5.0 | 6.0 | 6.0 | 6.0 | 8.0 | 8.0 | 8.0 | 8.0 |

| Designation | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 | ST6300 | ST7000 | ST7500 |

| Top Cover ≧ | 8.0 | 8.0 | 8.0 | 8.0 | 8.5 | 9.0 | 10.0 | 10.0 | 10.0 |

| Bottom Cover ≧ | 8.0 | 8.0 | 8.0 | 8.0 | 8.5 | 9.0 | 10.0 | 10.0 | 10.0 |