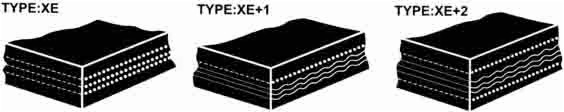

Cross Stabilized Base Belt

DESIGN

It is based in the following main components:

(1) Cross-stabilised Base Belts

(2) Sidewalls

(3) Cleats

(2) Sidewalls

(3) Cleats

Sidewall Conveyor blet has been designed with two corrugated sidewalls and cleats

molded to cross-rigid base belt can carry heavy product loads up to the inclined angle

of 75° This belt is popular to be used where space where space is at a premium and

steep incline angles are desired.

molded to cross-rigid base belt can carry heavy product loads up to the inclined angle

of 75° This belt is popular to be used where space where space is at a premium and

steep incline angles are desired.

The Base Belt :

The base belt is designed to bend efficiently in a longitudinal direction and has greater rigidity in a transverse direction by utilizing reinforced fabrics with monofilament the creates a fabric carcass of high tension.

The base belt is designed to bend efficiently in a longitudinal direction and has greater rigidity in a transverse direction by utilizing reinforced fabrics with monofilament the creates a fabric carcass of high tension.

Features:

It can be deflected from the horizontal to an incline or vertical and back again without bowing or sagging. These deflection points as well as the belt returning on free lateral space by snub idlers definitely require the corss-rigidity of the base belt. The designed mno-filament fabrics provide better returnside support, no wear and tear of cleat and cover rubber is available with various compounds like abrasion resistance oil, heat, flame resistance.

It can be deflected from the horizontal to an incline or vertical and back again without bowing or sagging. These deflection points as well as the belt returning on free lateral space by snub idlers definitely require the corss-rigidity of the base belt. The designed mno-filament fabrics provide better returnside support, no wear and tear of cleat and cover rubber is available with various compounds like abrasion resistance oil, heat, flame resistance.