Raw Mix Proportioning

Accurate data on the chemical composition of raw mix as it is fed to the raw mill can dramatically reduce the cost of production and increase product quality.

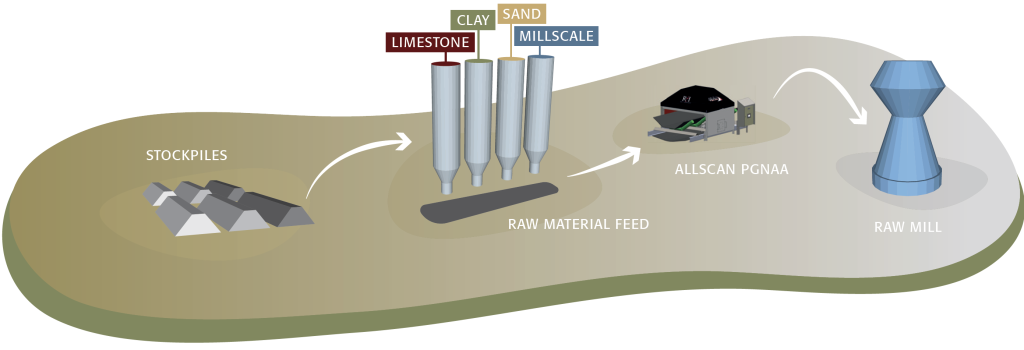

Neutron activation cement analyzers are commonly installed in cement mills producing 5000 tons per day of clinker where they are used to control the raw mix bin weighfeeders. Typically, the AllScan cross-belt elemental analyzer is installed on the conveyor upstream of the raw mill and downstream of the feeders where it continuously measures the chemistry of the raw mix. This data is relayed to specialist raw mix proportioning software that controls dosing from the corrective feeder bins according to pre-defined quality parameters such as LSF.