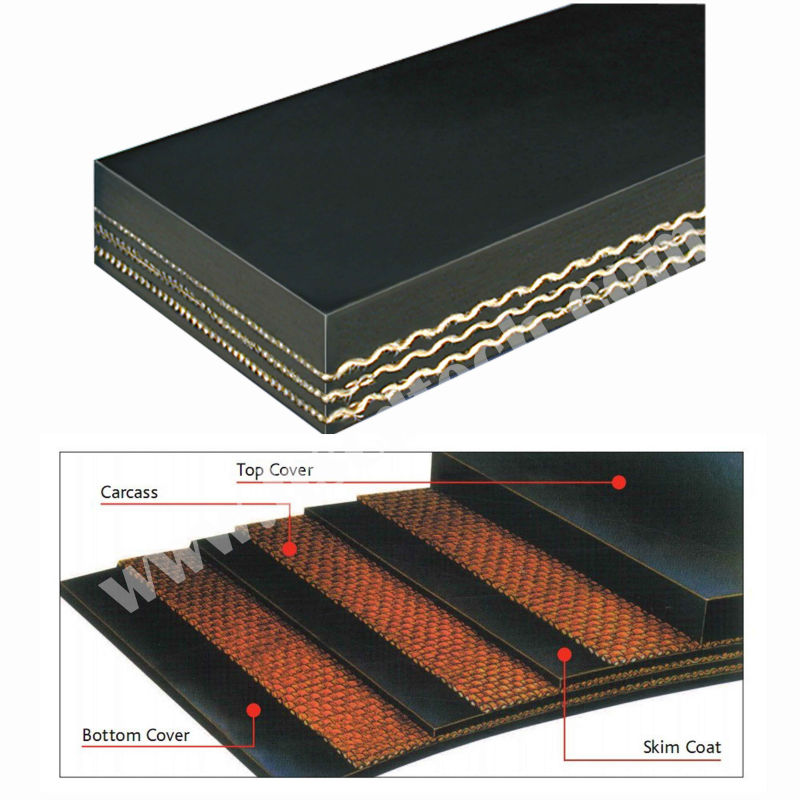

Anti-Acid And Anti-Alkali Conveyor BeltsSpecifications (1)Structure of the belt: The belt core can be made of cotton canvas, nylon canvas and polyester canvas, the cover rubber is made of acid and alkali resistant material; (2)Characteristics and advantages: Good elastic belt body, good grooving performance, low elongation rate and erosion resistant; (3)Applications: Widely used in chemical factories, cement making plant, fertilizer manufacturing and paper making works. |

Type of Fabrics & their features:

Nylon/Nylon (NN) Carcass:

NN 100, NN 125, NN 150, NN 200, NN 250, NN 300, NN 350, NN 400 and NN 450.

¤ Lower longitudinal elongation

¤ Higher tensile strength

¤ Good flexibility and trough ability

¤ Good resistance to mildew, moisture and rotting

¤ Good resistance to edge wear

¤ Excellent impact resistance

¤ Unaffected by alkalis and weak acids

¤ Suitable for conveying material over long distances

Polyestor/Nylon (EP) Carcass:

100, EP 125, EP 150, EP 200, EP 250, EP 300, EP 350, EP 400 and EP 450

¤ Besides having the advantages as listed for NN carcass belts, EP belts have the additional advantage of lower longitudinal elongation.

Cotton/ Cotton (CC) Carcass:

28 OZ, 32 OZ, 36 OZ, 42 OZ, 48 OZ and 34 OZ.

¤ Suitable for most applications

¤ Good bonding for rubber

¤ Good fastener holding properties

GRADES:

- N Grade Rubber Conveyor Belt

- M Grade Rubber Conveyor Belt

- Crows Foot Weave (CFW) M Grade Rubber Conveyor Belt

- QuarryMaster Rubber Conveyor Belt

- MOR Oil Resistant Nitrile Rubber Conveyor Belt

- HOR Heat & Oil Resistant Nitrile Rubber Conveyor Belt

- Heat Resistant Rubber Conveyor Belt

- E Grade Anti Static Grain Handling Rubber Conveyor Belt

- FRAS Rubber Conveyor Belt

- Steel Cord Rubber Conveyor Belt

- Chevron Cleated Rubber Conveyor Belt

HYGIENIC: This grade is specially manufactured from suitable non-toxic elastomers & is odorless. Recommended for handling foodstuff like tea, bakery, medicines, confectionery etc.

Special features of HSCD Conveyor Belts:

1. Unique Carcass Design & Assembly.

2. Superior Adhesion Levels.

3. Higher Longitudinal Flexibility.

4. Improved Transverse Flexibility.

5. Higher Tensile Strength.

6. Low Belt Stretch.

7. Outstanding Impact Resistance.

8. Improved resistance to mechanical damages.

9. Higher carrying capacity with low conveyor belt weight.

10. Rot Resistance.

11. Hot & cold splice proven.

12. Superior joint efficiency & increased life.

13. Universal applications.