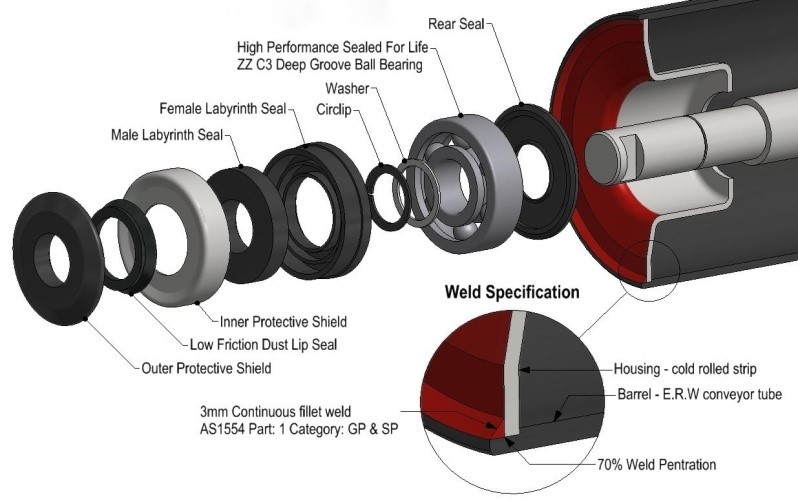

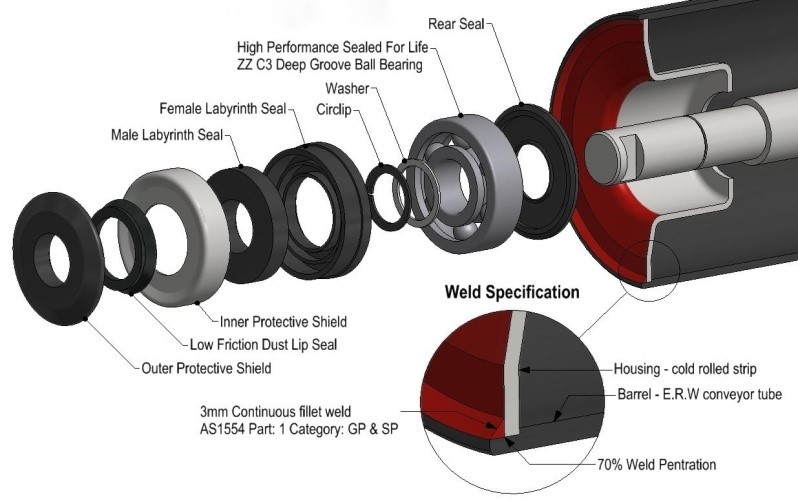

STEEL RETURN CONVEYOR ROLLERS

Monster’s steel conveyor rollers are available in a range of standard off the shelf sizes, or can be custom

steel conveyor ilder

made to your requirements.

All rollers feature primary and secondary dirt seals, deep groove ball bearings and ERW tubing with MIG welded ends. Shafts are stepped as required.

IMPACT ROLLERS

impact rollers

Deployed in the impact (loading) area of a conveyor belt, the rubber rings prolong belt and system life by absorbing the impact energy of the media being loaded. The rubber rings are secured to the steel by retaining clips and/or vulcanisation.

Impact rollers are available in standard or FRAS rated configurations.

Disc Return Roller

Fitted to the return side of the belt the open spaces between the rubber discs reduce media carry back.

K-Return Disc Idlers

Spiral return rollers are also available.

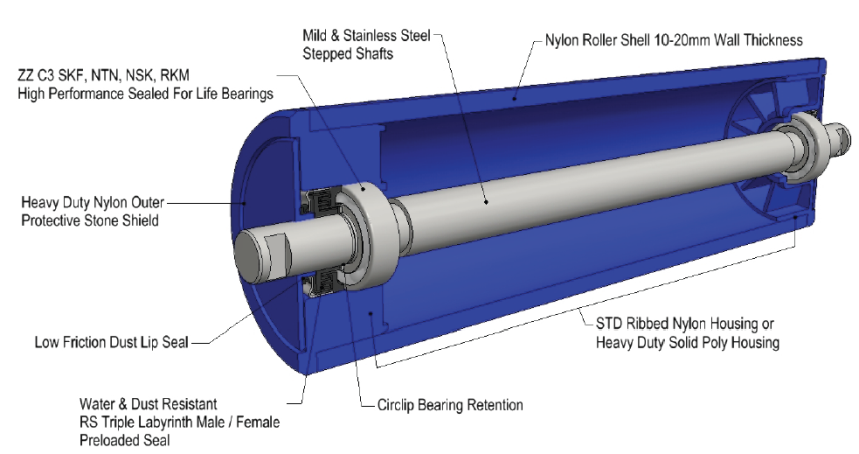

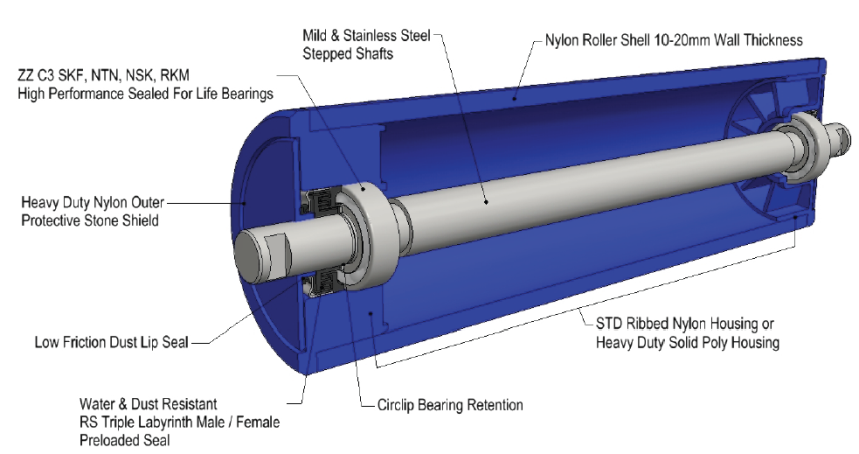

Polymer Conveyor Roller

Lighter in weight, corrosion resistant and producing less noise, polymer rollers have advantages in many

Polymer Conveyor Roller

specialised situations. Available in Nylon or Polyethylene, with or without a steel reinforcement, there is a polymer roller for just about every application.

HDPE conveyor rollers

Corrosion resistance HDPE conveyor rollers

Designed to handle the same capacity as an equivalent steel roller, the Monster provides a non-corrosive shell and additional static face sealing system to further limit the ingress of dirt.