Sidewall belt conveyor for coal industry

Sidewall conveyor belts are suitable for steep angle conveying (up to 90°) of general and bulk

goods. This can reduce the number of transfer points during operation. This has a positive

outcome in terms of producing a mode of operation that saves energy and capital.

Cleat information for the Sidewall belt conveyor for coal industry

Cleat types: T, TS, C, TC and TCS

The cleat is made of enforced fabric, solid, anti-shock to avoid distortion.

“TS” and “TCS” cleat are normally used for abrasion condition

“T” and “TS” cleat are normally used up to 40 degree

“TC” and “TCS” are normally used from 40 degree to 90

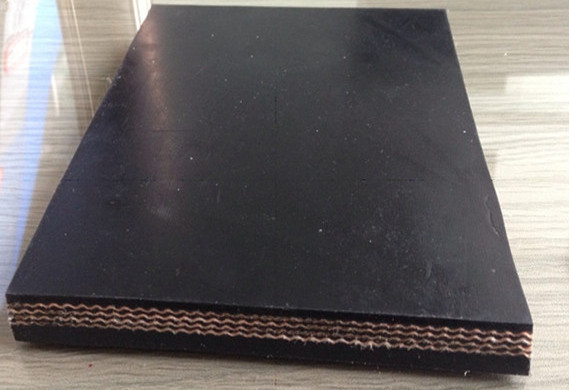

Base Structure of sidewall conveyor belt

Four parts: Top cover rubber; Bottom cover rubber;

Reinforced core; Cross rigid.

Thickness of top cover rubber: 3-6mm;

Thickness of bottom cover rubber: 1.5-4.5mm.

Belt core: Cotton, Nylon, EP or Steel Cord